WATER TANK CLEANING

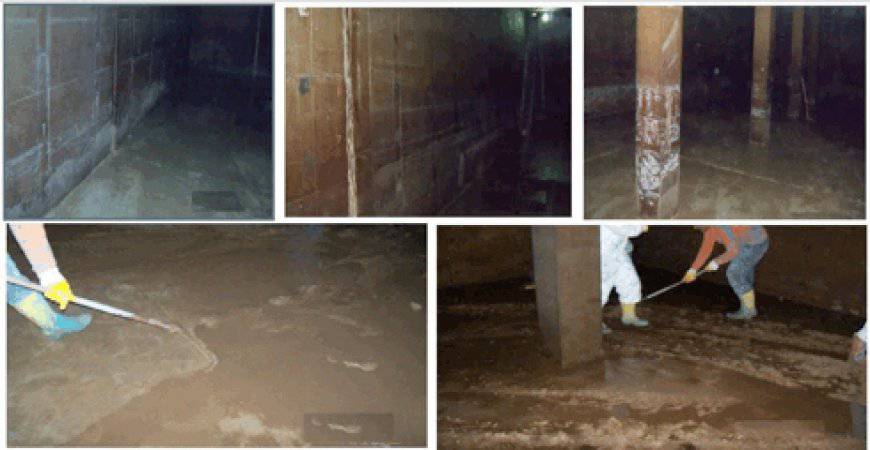

Even if the water in the water tanks is not used for drinking water; Microbes (Cholera, Typhoid, Dysentery, etc.) formed in the water tanks enter the human body as a result of using the bathroom and toilet, washing dishes and laundry, brushing teeth, and cleaning the house. Rust and mud accumulation in the water tanks clog the filters of washing machines and cause them to deteriorate. During the cleaning, it was observed that dead cat and mouse, worms and maggots living in water, fungal and bacterial formations, and mud deposits came out of the water tanks.

In order to completely destroy the dirt, rust and manganese layers in the water tanks, it is not enough to wash with water using substances such as soap, detergent, bleach. Such cleaning does not destroy manganese and other harmful substances, and it is not a hygienic cleaning. Hygienic cleaning is important in water tanks. This is possible with special cleaning agents developed for water tanks cleaning.

Chemical and biological changes in dirty water tanks cause the reproduction and spread of many disease microbes by reducing or destroying the activity of chlorinated water coming from the network to your water tanks. Unknowingly, we use this water to brush our teeth, shave, wash our vegetables, take a bath, and cause infectious diseases. Drinking or using these waters leads to infection.

In order to prevent such formations in the water tanks, the cleaning of the water tanks must be done at least 2 times a year by using chemicals and techniques specially produced for water tanks cleaning. In addition, the inside of the water tanks must be covered with antibacterial paints and coatings.

CORROSION IN WATER TANKS

What is Corrosion? How is it formed?

It is the deterioration or loss of properties of a metal or metal properties as a result of the reaction with its environment. Other than steel, materials such as wood, concrete, fiber and plastic may corrode. The rate and direction of corrosion may change depending on the properties of the material or the environment they are in or the other substances they are in contact with.

Corrosion affects the materials and devices we use in a short time, causing them to deteriorate, fail to function, and eventually become disabled.

Corrosion generally occurs in building materials and most often in metals. Steel is the most widely used metal in construction and water tanks. Steel components contain 95% iron. Iron combines with the oxygen in the atmosphere and water to form rust or iron oxide, which is formed as a result of corrosion. During the formation of iron oxide, the metal starts to deplete, loses its desired properties, sooner or later loses its thickness and cannot fulfill the tasks expected from its design.

Ways to Prevent Corrosion

In order to prevent corrosion, first the metal must be coated and the contact of iron with oxygen must be cut off. The simplest and most widely used method today is galvanization or coating with different methods and types of paints.

During the production of steel, corrosion resistant materials (Chrome, Manganese etc.) can be mixed to make the metal more resistant to corrosion. Stainless and alloy steels are some of them.

Does Corrosion Just Corrode Your Tank?

There are many damages that corrosion will cause to your water tanks or you. If early measures are not taken, corrosion will rot your tank in a certain period of time and reduce its strength. As a result, your tank may explode or become out of use. Apart from these, the surfaces where corrosion occurs in the corroded water tanks become rough and become a nest of dirt and germs. The iron oxide formed by the corrosion can affect our health by contacting the microbes and bacteria in the water with the water we use for cleaning, to our body. At the same time, corrosion wastes not only disrupt and block the devices you use in your home and workplace, but also carry corrosion to them.

Does Stainless Water Tanks Rust?

Although its name is "Stainless", it rusts very quickly when it finds its environment, especially by being affected by some undesirable substances in the water.

Especially waters with high conductivity and chlorine-containing water used as a germ-breaker are the mortal enemies of stainless. Water with this feature destroys the stainless steel by corroding very quickly. As a result, the STAINLESS TANK RUNS.

The Most Effective Way to Prevent Corrosion

One of the ways to prevent corrosion is the galvanizing method.

In this method, the steel is coated with zinc and other additives by galvanizing method in hot baths. Although this method is the most effective method for coating the metal, the zinc contained in the galvanization is a harmful substance for human health. For this reason, galvanized tanks cannot be used as drinking water tanks. Despite this, especially build-and-sell contractors for flats have their drinking water tanks made from galvanized metal. Let it pass through the settlement is enough logic gives them this right. Fire water, utility water and utility water can be stored in galvanized tanks.

Another way to prevent corrosion is to coat the metal. (Painting) However, the type of paint used and the method of application to the metal are very important.

It is very important to prepare the metal surface in a way that it will accept and adhere to the paint before painting. Otherwise, even if the best paint and coating material in the world is used, it will not work unless it adheres to the metal in a compatible way and it will throw the paint off the metal. To prevent this, the metal surface must go through phosphating, pickling, sandblasting or degreasing processes before painting.

The paint types used in metal painting are very diverse, depending on the metal and the environment in which the metal will be used. The main paint type used in water tanks is epoxy based paints. Solvent-free epoxy paints should be preferred especially for painting drinking water tanks. The most important feature of solvent-free paint is the absence of solvent, which can dissolve in water when it encounters water and is very harmful to human health.

What is Liquid Membrane and How Is It Applied?

Liquid membrane is a polyethylene and polyurethane based coating material used especially in drinking water tanks. It is a two-component coating applied after a pre-primer paint is applied after the surface preparation pre-treatments (phosphating and sandblasting) on the water tanks surfaces. It does not react with water, it does not contain any additives that can dissolve or mix with water, it is very flexible, it has superior mechanical and chemical properties that do not wear out or wear out. It can also be used for drinking water with 'NSF or WRUS' certificates of conformity with food regulations. It is an alternative to the stainless tank and is not affected by the most corrosive substances and chemicals in the water.

CORROSION IN WATER TANKS

CORROSION IN WATER TANKS

What is Corrosion? How is it formed?

It is the deterioration or loss of properties of a metal or metal properties as a result of the reaction with its environment. Other than steel, materials such as wood, concrete, fiber and plastic may corrode. The rate and direction of corrosion may change depending on the properties of the material or the environment they are in or the other substances they are in contact with.

Corrosion affects the materials and devices we use in a short time, causing them to deteriorate, fail to function, and eventually become disabled.

Corrosion generally occurs in building materials and most often in metals. Steel is the most widely used metal in construction and water tanks. Steel components contain 95% iron. Iron combines with the oxygen in the atmosphere and water to form rust or iron oxide, which is formed as a result of corrosion. During the formation of iron oxide, the metal starts to deplete, loses its desired properties, sooner or later loses its thickness and cannot fulfill the tasks expected from its design.

Ways to Prevent Corrosion

In order to prevent corrosion, first the metal must be coated and the contact of iron with oxygen must be cut off. The simplest and most widely used method today is galvanization or coating with different methods and types of paints.

During the production of steel, corrosion resistant materials (Chrome, Manganese etc.) can be mixed to make the metal more resistant to corrosion. Stainless and alloy steels are some of them.

Does Corrosion Just Corrode Your Tank?

There are many damages that corrosion will cause to your water tanks or you. If early measures are not taken, corrosion will rot your tank in a certain period of time and reduce its strength. As a result, your tank may explode or become out of use. Apart from these, the surfaces where corrosion occurs in the corroded water tanks become rough and become a nest of dirt and germs. The iron oxide formed by the corrosion can affect our health by contacting the microbes and bacteria in the water with the water we use for cleaning, to our body. At the same time, corrosion wastes not only disrupt and block the devices you use in your home and workplace, but also carry corrosion to them.

Does Stainless Water Tanks Rust?

Although its name is "Stainless", it rusts very quickly when it finds its environment, especially by being affected by some undesirable substances in the water.

Especially waters with high conductivity and chlorine-containing water used as a germ-breaker are the mortal enemies of stainless. Water with this feature destroys the stainless steel by corroding very quickly. As a result, the STAINLESS TANK RUNS.

The Most Effective Way to Prevent Corrosion

One of the ways to prevent corrosion is the galvanizing method.

In this method, the steel is coated with zinc and other additives by galvanizing method in hot baths. Although this method is the most effective method for coating the metal, the zinc contained in the galvanization is a harmful substance for human health. For this reason, galvanized tanks cannot be used as drinking water tanks. Despite this, especially build-and-sell contractors for flats have their drinking water tanks made from galvanized metal. Let it pass through the settlement is enough logic gives them this right. Fire water, utility water and utility water can be stored in galvanized tanks.

Another way to prevent corrosion is to coat the metal. (Painting) However, the type of paint used and the method of application to the metal are very important.

It is very important to prepare the metal surface in a way that it will accept and adhere to the paint before painting. Otherwise, even if the best paint and coating material in the world is used, it will not work unless it adheres to the metal in a compatible way and it will throw the paint off the metal. To prevent this, the metal surface must go through phosphating, pickling, sandblasting or degreasing processes before painting.

The paint types used in metal painting are very diverse, depending on the metal and the environment in which the metal will be used. The main paint type used in water tanks is epoxy based paints. Solvent-free epoxy paints should be preferred especially for painting drinking water tanks. The most important feature of solvent-free paint is the absence of solvent, which can dissolve in water when it encounters water and is very harmful to human health.

What is Liquid Membrane and How Is It Applied?

Liquid membrane is a polyethylene and polyurethane based coating material used especially in drinking water tanks. It is a two-component coating applied after a pre-primer paint is applied after the surface preparation pre-treatments (phosphating and sandblasting) on the water tanks surfaces. It does not react with water, it does not contain any additives that can dissolve or mix with water, it is very flexible, it has superior mechanical and chemical properties that do not wear out or wear out. It can also be used for drinking water with 'NSF or WRUS' certificates of conformity with food regulations. It is an alternative to the stainless tank and is not affected by the most corrosive substances and chemicals in the water.